< Back to Rhodes 18

Wednesday

With 120 grit paper on a finishing sander, I sanded the second round of epoxy filler on both hull and deck as required, more or less completing the surface prep work in these areas. There’d likely be another round of fine filler following high-build primer.

Next, I turned to the interior, which required a few minor repairs, including the mast partners, an existing (ugly) repair on one of the cockpit seats, and some additional reinforcement on a pair of fiberglass “fillets”, for lack of a better term, located at the base of the centerboard trunk, which were fairly lightweight and, on the starboard side, cracked where it met the trunk.

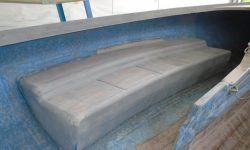

I removed the remnants of paint from the centerboard trunk fillets, allowing room to re-tab them with new material and epoxy resin and to prepare the surfaces for proper bonding. The cockpit seat repair, located on the starboard side, was structurally sound, and while I’d at first intended to remove it and redo as needed, it was well-stuck enough that I settled for cleaning up the pools of excess resin and the material located over one of the molded grooves in the cockpit seat; I’d work with the repair from this point. Afterwards, I cleaned up the cockpit to prepare for new work.

I opened up the mast partners opening a bit more, then masked over the bottom side and filled the damaged starboard side with an epoxy mixture comprised of high-density filler and silica. I left the undamaged side alone; the new material would allow me to recreate the opening later, before reinforcing the repair with new fiberglass.

I reinforced the centerboard trunk fillets with new tabbing, extending well onto the trunk and bottom of the hull, set in epoxy resin. This wasn’t a structural fillet, and didn’t appear to be original; rather, it seemed to be some sort of cosmetic, ergonomic thing added by a previous owner. The intent of the reinforcement was to repair the existing setup, not to provide any particular additional strength to the boat or centerboard trunk.

The interior would receive a simpler paint process, but even so the cockpit seats required skim-coating and basic filling and fairing before I could proceed, so I took care of this next, following the same process as on the hull and deck to force fairing material into the larger cracks and crazing, as well as clean up some of the existing work.

To round out the day, I replaced the masking tape at the waterline scribe mark; the tape I’d put on earlier had been beat up by the sanding work, and the new tape would remain in place during the priming and painting steps coming up.

Total time billed on this job today: 5 hours

0600 Weather Observation:

45°, sun and clouds. Forecast for the day: sun, then showers during the afternoon, 70s.