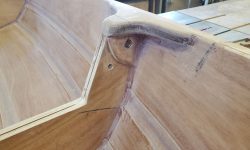

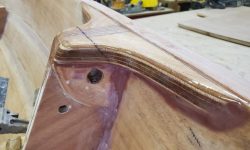

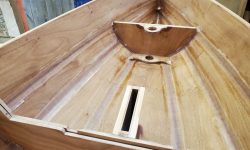

I removed the taped-down aft seat covers to reveal the new blind fillets. The fillets came out well, and the seat tops came off with no issues.

Afterwards, I lightly sanded the glossy tops of the fillets, and sanded back their sharp and thin outer edges just a bit to remove the knife edge. I also sanded the bonding areas of the underside of the tops, and, following the directions (which were confusing here) removed all the tongues from the top. Later, I found the instructions had meant only the outboard tongues on the long, hull sides of the tops–not the pair on the transom side of each top–but this was of no matter since alignment of the seats was already well-established by the fillets, and in any event what was done was done.

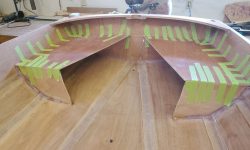

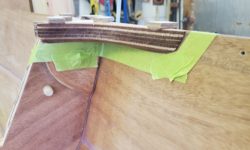

Next, I securely taped the interior side panels in place so I could permanently install them with fillets on the inside. I fully taped the joints where the panels met the transom and hull, and added more tape to hold the panels securely at the ends and where they met the hull. Then, I installed epoxy fillets on the inside corners to tie these in with their adjacent parts. I used fast hardener for this mix so that the fillets might cure enough before the end of the day to allow me to install the seat tops, rather than wait till a new day.

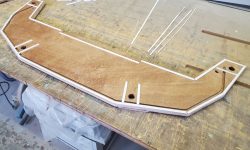

While giving the fillets time to cure, I worked on fitting the foredeck. Final installation wouldn’t happen till after I cut the boat in half, but now seemed as good a time as any to get the fitting done, and move on with a couple final steps that had to happen before final installation.

Initially, the foredeck fit fairly well, but was too tight at the aft end where it met the bulkheads, and also a bit tight in several places around the hull edges; the net result of this was that I couldn’t pull the assembly far enough aft, nor down far enough to bear on the mast step and bulkhead, and the daggerboard, cleats, and aft bulkhead. I took these blind photos to help me determine how the foredeck was riding below the surface.

The directions pointed out that the framing members of the foredeck might hit the forward end of the daggerboard trunk, limiting aft movement, and I found this to be so, so in addition to slightly modifying the aft corners of the foredeck to better fit around the bulkhead, I also sanded back the upper portion of the daggerboard trunk and support cleats to increase clearance there. It took several fits and starts and various trimming of the foredeck sides, slightly widening the gaps in the mast step bulkhead for increased clearance for the reinforced edges of the foredeck, and other minor adjustments till I got the foredeck to fit down tightly on the required bearing surfaces (mast step and bulkhead, daggerboard, and aft bulkhead/cleats).

The foredeck had a slight tendency to warp, so unless I pressed down on the aft end, there was a small space there, but it required only light finger pressure to close it. so overall I was satisfied with the position. The foredeck was flush with the aft edge of the forward part of the double bulkhead, and as directed I added two alignment nails here.

Next, reaching beneath the foredeck through the hatch, I marked the position of the mast hole through the upper partners, and also traced out the borders of the bulkheads and other bearing members for reference. With the foredeck back on the bench, I drilled a 1/2″ hole through the center of the mast partners mark, enlarged it slightly to fit a router bit, then, with the foredeck back in position on board (and aligned with those small nails again), I trimmed the mast hole to match the partners beneath.

Now I could lightly sand the bottom of the foredeck (coated previously with one coat of epoxy), paying extra attention to all the marked bearing surfaces, and after cleaning up I applied a second and final coating of epoxy to the entire underside, including framing members, the aft edge of the seat tongue, and the inside of the hatch opening.

For the afternoon, there were two main tasks I wanted to do: install the aft seat tank lids, and install the mast tube. The mast tube installation required that the boat be blocked at the aft end so that the tube would be vertical, so I started with that, figuring it would take an extra block or two. Imagine my surprise when it required four 2x4s, two 3/4″ pieces of scrap, and a 1/4″ piece of plywood (all added piecemeal and with increasing dismay) to get the mast tube finally vertical. The dismay arose because, since I didn’t want to move the boat around at all during either of the next chosen tasks, this meant that I’d have to work over the much-higher gunwale to install the aft tank tops. It wasn’t the end of the world, but was an example of my greed for progress sometimes making things more difficult than they needed to be.

In any event, with the boat thusly positioned and ready for action, I started by stabilizing the boat a bit with a couple long clamps at the forward end, just to keep the boat from its propensity to tip one way or the other.

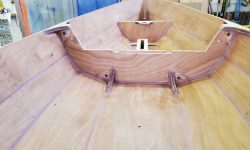

Working over my shoulder-height aft gunwale, with the assistance of a little step platform I’d previously built for some long-forgotten need, I installed the aft seat covers, beginning with a dry fit, during which I installed alignment nails on the inboard edges of the seat covers to hold them during installation, and followed by an epoxy coat of the inside of the tanks and underside of the seats. The fillets I installed earlier in the day were well-gelled by now and safe for these additional steps.

I applied plenty of thickened epoxy around the bearing surfaces, then installed the tops, securing them with wooden pressure clamps cut to appropriate lengths beneath the transom inwale, and clamped sticks along the outer edges, plus lots of masking tape on the two inner edges to secure them as needed. I cleaned up all the excess epoxy and left the lids to cure overnight. The extra height of the stern made this all more work than it might have been, but such was the price of stunning progress.

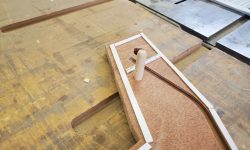

Finally, I installed the mast tube as directed. After confirming the tube was still vertical, I sanded the two ends a bit (where they’d bond to the respective mast partners), then mixed a one-pump batch of epoxy, with a small amount of structural filler mixed in, till it was just-still pourable/level-able, and poured this into the lower mast partner. As directed, this filled the hole to about 3/16″ deep. I installed the mast tube and held it in place with small wedges on each side to hold it centered in the hole (at both mast partners). Then, at the top partner, I applied a small fillet around the bottom edge where the tube passed through to basically seal up the gaps from beneath, which would be required for the next step in the installation process.

That would happen next time. Now, the day was done, and I left the boat strictly alone so the pooled, leveled epoxy could cure undisturbed.