March 11, 2020

August West 3

Wednesday

After lightly sanding the new seahood fiberglass at its trailing edge, I test-fit the hood once more. It fit well, and the curvature was what it needed to be to clear the sliding hatch.

I temporarily reinstalled the wooden hatch trims to ensure that the sea hood fit around them properly. I found that these forced the sides of the sea hood out just a bit, flattening the curve and causing minor interference issues, so with the trims removed once more, I beveled the cuts to match the inside angles of the sides of the sea hood, and this cured the problem. Satisfied now with the fit, I used a drill and a small bit to mark the deck at each of the screw holes in the sea hood mounting flange.

After removing the hood again, I applied a coat of fairing compound to the after reinforcement to fine-tune its shape and those of the fillets and surrounding area.

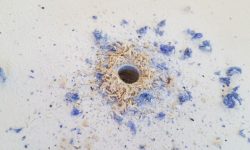

Back on the boat, I used a 1/2″ bit to drill out the top laminate and core from the new fastener locations for the sea hood. The core was dry in all areas, but the spoils highlighted an interesting blue color to the laminate that I’d not seen before; this was present at all hole locations. After cleaning up, I masked around the holes as needed and filled them with a thickened epoxy mixture, leaving this to cure while I worked on other things.

While I had the hatch off, it made sense to begin the wood stripping with the small trim pieces on the sliding hatch. Once I’d sanded the wood clean, I installed bungs in the exposed screw holes on the top trim.

On deck, I decided to continue with the companionway hatch trim and work my way out from there, so to begin I removed the two vertical pieces of trim flanking the companionway–these had no bungs, and, as it turned out, not a stitch of sealant–and sanded them clean down on the bench. Then, I reinstalled them with some butyl sealant behind, and later installed new bungs in the open screw holes.

Continuing, I turned to the trim just inside the companionway opening, which was partially finished (sides) and partially bare (forward). With heat and a scraper, I removed the heavy, dark finish from the sides, then sanded clean the bare wood.

To finish up the day’s work on this project, I installed new bungs in the handrails, and the starboard cockpit coaming. I’d be able to sand these smooth at the same time I stripped and sanded these parts, saving some time later.

Total time billed on this job today: 5.5 hours

0600 Weather Observation: 36°, partly clear. Forecast for the day: Mostly sunny, 44°