110 Cookson Lane | Whitefield, ME 04353 | 207-232-7600 | tim@lackeysailing.com

Summer Song | Friday, January 3, 2014

I continues with the list of odds and ends and preliminary work leading up to the two most significant jobs on this season's project list.

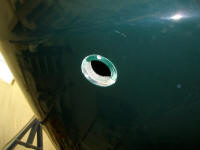

The new engine would require a larger diameter exhaust system--2"--so I removed the existing exhaust outlet in the counter and replaced it with a new bronze fitting of the correct diameter. I had to cut the old fitting from the inside in order to remove it, but otherwise the job was straightforward.

The existing hole was just undersized, so I used a drum sander to enlarge it enough for the new fitting. Then, after drilling and tapping fastener holes, I installed the new fitting with plenty of sealant, machine screws, and nuts and washers within.

I could get a head start on the new engine controls as well. To replace the old controls, which had been split between both sides of the cockpit, I selected a Vetus SISCO single-lever control unit, which I installed on the starboard cockpit well so that the new hole would absorb the hole left from the old control's removal.

Using the supplied installation template, I marked and drilled four 2" holes and cut out the remains with a saw, before temporarily installing the control with four machine screws. I'd remove it to make up the control cable connections a little later, but first I measured for and ordered new control cables.

In the head, I masked off as needed to prepare for upcoming primer and paint.

In order to rebuild the toerail, and specifically the forward section at the stem, I needed to remove the cast bronze stem fitting, which overlapped the wooden rail sections. In order to remove the stem fitting, I had to remove the bow pulpit, which was of a design common to the period that incorporated a single forward stanchion supported by a stud on the stem casting itself.

Removing the pulpit was straightforward enough: after disconnecting the lighting wires in the chainlocker, I removed the nuts and washers, and backed out the screws, all of which were new just a couple years before when I repainted the decks and rebedded all the hardware. The pulpit came off easily afterwards.

The stem casting was more of a challenge, thanks in large part to the tough access at the tip of the stem, at the very extent of my longest reach, exacerbated by some bulky and sharp original fiberglass work that obscured some of the nuts securing the stem casting. There were three large bolts through the stem itself, which were relatively accessible (in the same way that 0° is relatively warm compared to -20°), but the two smaller fasteners through the top of the fitting were nearly impossible to access from beneath--or, more specifically, one (port) was completely impossible, while the second was only severely difficult.

I clamped locking pliers onto the nuts where I could--the three stem bolts plus the starboard top bolt--and from outside the boat used an impact gun to back out the fasteners, which was still challenging but at least was successful.

All traditional attempts to remove the port upper bolt, with its hidden nut beneath, failed, and eventually I drilled out the head of the screw from above, finally releasing the stem casting.

Total Time Billed on This Job Today: 5.75

Hours