110 Cookson Lane | Whitefield, ME 04353 | 207-232-7600 | tim@lackeysailing.com

Snow Lily | Wednesday, May 29, 2013

The weather was too wet to traipse around on the boat, so instead I stayed in the shop and took care of various small things. A box full of tin-plated copper buss bars for the battery bank connections had arrived, and I unwrapped them for inspection and later use.

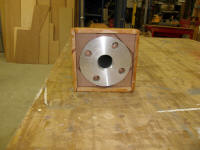

Now that the varnish work on the interior table was complete, I completed a few final construction steps, beginning with the threaded flange on the table itself. To secure the flange, I installed threaded inserts in the bottom of the table, and then used 1" hex bolts to secure the flange.

Next, I installed drop leaf hinges and a pair of extendable support arms for the leaf.

I drilled a hole in the wooden leg base to accommodate the aluminum structural leg.

Looking for a table height of around 29", I cut off the excess length of the square-sectioned wooden leg, allowing room at the top for flange clearance beneath the table, then cut off the aluminum leg to the correct length, allowing for the thread engagement in the flange and the thickness of the table top. Afterwards, I rethreaded the end of the leg. After positioning the two wooden parts together in the proper position, and marking the boundaries with tape, I secured the leg and base together with screws from the bottom side.

To keep the structural aluminum leg centered and prevent the wooden leg from moving around, I installed a piece at the top to secure the round leg, and also installed triangular pieces in the base section to keep the base registered properly around the flange. The flange would be secured permanently to the cabin sole a little later on, but the other components of the table would allow its removal should it be desired.

Total Time on This Job Today: 3.5 hours