110 Cookson Lane | Whitefield, ME 04353 | 207-232-7600 | tim@lackeysailing.com

Snow Lily | Thursday, June 13, 2013

There had been a couple frustrating, long-term backorders/delays on some more or less non-critical equipment, but fate smiled upon the project and saw these final items (a 48V inverter that the owner ordered, and two Vetus stainless steel "Dorade" vent bases) arrive just in the nick of time before the boat was scheduled to depart the shop. Both of these items had been ordered months earlier.

I selected these newly-available stainless steel Vetus cowl vent bases in lieu of the original boxes that had been part of the deck at the onset. I liked the simplicity and theoretical effectiveness of the design, and minimal bulk and appearance. Like the complicated and bulky boxes that inspired them, these vents (as described) provided indirect airflow through the large cowls, allowing water to escape harmlessly through the bottom rather than into the cabin, and also included internal screens and a shutoff feature for the heaviest weather.

The only problem was that they were not yet available, but I'd been promised them by early May. The fact that they arrived in early June instead turned out to be a minor inconvenience, but fortunately the timing worked out acceptably despite it all. Along with the Dorade bases, I selected two 3" diameter SS cowl vents.

During the structural phase of the project oh so long ago, I'd prepared the deck in way of these vent openings (one in the head, one in the passageway) with solid fiberglass inserts to protect the coring in these large holes, then glassed (and eventually painted) right over the top. So during the boat's time spent outdoors since the completion of major project work, there'd been no issue with the backordered items.

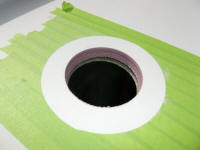

After enduring several days of rainy weather that arrived right after the backordered vents themselves, I took advantage of the first dry morning to install the vents. This was a straightforward process. First, I drilled pilotholes from beneath (where the old openings were still visible in the overhead), then, after masking off the deck for protection, drilled 3-3/4" holes through the deck from above. With the vent bases dry-fit, I cut away the masking tape around the base.

I applied beads of sealant to the vent base itself, as well as to the deck around the holes, then pressed them into position and, from below, installed threaded trim rings that not only finished off the openings beneath, but secured the vents above--along with the adhesive properties of the Sika 291 polyurethane sealant.

After cleaning up any excess sealant, I installed the cowl vents from above. The vents featured a threaded trim ring to secure them to the bases, and allowed the vents to face any which way conditions might dictate.

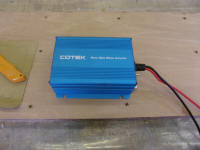

I'd jealously guarded a prime section of electrical locker real estate for the Cotek inverter, feeling increasingly defensive as the locker filled up with other things. But my tiny space remained, and installing the inverter was a matter of a few screws; the wire leads from the inverter were the perfect length to run out to the switch in the main panel, which I'd already wired into the ship's electrical system, so I was pleased with the alacrity of the installation.

Afterwards, I tested the inverter for operation, indicated by the small green status light. I also briefly plugged in the only AC appliance I happened to have close at hand--a small vacuum--and confirmed that even though the vaccuum's startup load was beyond the capacity of the inverter, the inverter did power the appliance. A split seconds' operation of the vacuum switch was all that was requried to confirm.

One additional final detail that wrapped this week was the completion of the canvas panel for the quarterberth, which panel closed off the space beneath the cockpit. Secured with a track beneath the cushion and easy-to-use pull-lock fasteners t the top and sides, this cover provided quick and full access to the battery compartment and switch as needed, while effectively and cleanly closing off the space.

All that remained was to give Snow Lily a quick washdown, and secure the boom on deck for transport on Friday, June 14, after which time final rigging, trials, and other details were to be completed.

Total Time on This Job Today: 6 hours