|

|

~MENU~ |

| Home |

| The Concept |

| The Boat |

| Bringing Her Home |

|

Weekly Progress Log |

|

Daysailor Projects |

| The Boat Barn |

| Resources |

| Other Sites |

| Email Tim |

|

|

|

Sidebar: AlexSeal Marine Paint System (LPU) |

AlexSeal was engineered and designed by the same person who, 30 years ago, created the product that became Awlgrip. As the story is told to me, this man's non-compete agreement with US Paint has now expired, following his leaving the company some time ago, and he has untaken the task of creating this new LPU system that enhances all that is good about Awlgrip, and improves upon its weaknesses (namely application and reparability). Awlgrip is a great product, but admittedly it is now old technology. Whether or not AlexSeal is a better product remains to be seen. However, I feel it is worth trying out on this project, and I look forward to using something new. All I know about is my tiny little corner of the world here, but Hinckley, Morris, and a number of small-volume, high-end local boatyards have all begun trying out this product on a variety of their projects--some for customer boats, some (Hinckley) for workboats and company-owned show boats. Pricing for AlexSeal is virtually identical to Awlgrip, so there is no benefit there one way or another. But if indeed the product exceeds Awlgrip as designed, then it may well be the wave of the future. AlexSeal Website |

|

During the process of building the Daysailor, I used several of the products in the AlexSeal line. Please see my descriptions and impressions of each product below, posted as I used them during the project. |

Alexseal

Fairing Compound Base 202 Alexseal

Fairing Compound Base 202Alexseal Fairing Compound Converter 252 This is a 2-part, 1:1 ratio epoxy fairing compound, with a very smooth texture, intended for coarse (or first-stage) filling and fairing. The two parts--white base and dark gray converter--are smooth and creamy, and mixed easily with a 6" knife on a flat board, making a light gray color when mixed. Application was straightforward and effective. The working time is quite long; I never ran into any problems with pot life. Cure time was significantely longer than other epoxy fairing compounds, at least at cooler temperatures. When cured, the material sanded easily. |

Alexseal

Super Build 302 Base Alexseal

Super Build 302 BaseAlexseal Super Build 352 Converter Alexseal Super Build 392 Reducer This product is the next in the line. It's an epoxy-based sprayable filler designed to even out imperfections in the previous layers of fairing compound--not only to fill these imperfections (such as minor sanding scratches, small voids, and so forth), but also to highlight any remaining areas that may require additional filling. |

|

Perhaps it was just the stock that I received, but the two components had settled badly, leaving very thick sediment that had to be reincorporated into the liquid portion of the two products. Fortunately, the base component comes in a very large can, but contains only one gallon; therefore, there was plenty of room to stir without worrying about spilling. The converter came in smaller can, but I was still able to stir it. I had to use a drill mixer to incorporate the converter back together; afterwards, both components contained some chunks that would not be stirred in. I didn't worry about the chunks during mixing of the two parts for application; I filtered them out just before pouring the mixed material into the spray gun, as I always filter the paint at this stage. This worked fine. A second gallon can of each product that I used for another project seemed to be in slightly better condition from the getgo. A paint shaker might have done a good job, but of course I don't have one of those. |

|

Application called for 2-3 coats of the product to a certain wet mil thickness. I did not have a mil thickness gauge (wet mil gauge) at the time, so did not use one in determining the paint thickness during application. I used the maximum amount of reducer (20% by volume) and found spraying quality to be good. The product remained quite heavy, as one would expect from a high-build, but runs were not a problem even when applying relatively heavy coats. I found 2 coats built up sufficiently to fill most minor scratches, but applied three coats to the deck and hull surfaces to ensure good coverage. The third coat was very light; I did it more to use up some mixed product than because the surface truly needed the extra material. |

|

There was little self-leveling, but the sprayed coat was relatively smooth. For sanding, I found that beginning with 120 worked well to mostly smooth the surface, after which I could truly flatten and smooth the surface with further sanding with 220. The primer sanded nicely and easily, though it created a very fine dust that hung in the air forever. The end result was flat and extremely smooth, and the primer did an excellent job filling small voids, sanding scratches, and other minor imperfections. It also highlighted any remaining areas that required additional filling. |

Alexseal

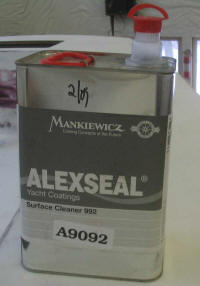

Surface Cleaner 992 Alexseal

Surface Cleaner 992I used this to wash the surfaces prior to painting, and after sanding, as directed. It's a strong solvent designed for the purpose, and safe to use over existing paint surfaces from the same system. |

Alexseal

Finishing Primer 401 Base Alexseal

Finishing Primer 401 BaseAlexseal Finishing Primer 451 Converter Alexseal Finishing Primer 491 Reducer The next product in line was the finishing primer. I bought two different colors--white and light gray--so that I could alternate between coats and make the spraying easier. A dark gray is also available. The product is designed to be mixed 2:1 with the supplied converter, with an additional 20% reduction with the appropriate reducer. As with the high-build primer above, I found the primer base to be badly settled in the cans. Breaking up the solid mass was extremely difficult, and resulted in lumps of material that could not be reincorporated into the liquid. Discussion with my supplier revealed that the manufacturer was aware of this particular issue and was working on some changes to provide a better product to the end user. A paint shaker probably would have worked to reincorporate the paint, but apparently the container size used (a large can of about 4-gallon capacity but containing only 2 gallons of product) made it a bad fit in most shakers. In any event, once I mixed the product together, the performance was as expected. Filtration just before adding to the spray gun took care of the chunks with no problem. The converter component was delivered in quart-size cans, even though I ordered two gallons. Whether this was a supply decision or a packaging decision from manufacture I do not know, but in any case it made no difference; it was just curious. The converter was an amber liquid that presented no storage problems. I applied three coats of primer, alternating white-light gray-white. I found the light gray primer to somehow be easier to spray, and later tests showed it to also be easier to sand somehow. Interesting. Both colors were decently self-leveling and resulted in a smooth, fair surface. I found no propensity for the primer to form runs when sprayed, even when areas were slightly overloaded. Despite some self-inflicted equipment problems, the primer sprayed nicely and covered well, particularly the light gray. Later, I found it to be easy to sand smooth, and formed a very smooth, slick surface when sanded to 320 grit.

|

Alexseal

Premium Topcoat 501 Base Alexseal

Premium Topcoat 501 BaseAlexseal Topcoat 551 Converter Alexseal Topcoat 592 Reducer (Medium) As nice as any primers can be, nothing comes close to the quality of topcoat paints. The Alexseal topcoat looked to be extraordinary right out of the can. Inside the deep 1-gallon can, the product looked bottomless in depth, clean, white, and pure. (I also used a dark, dark green on another project, and the color depth and gloss was unfathomable.) In a fortunate change from the two primers, there was little or no settling in the topcoats, which, frankly, might have been unacceptable for such a fine finish. The mixing ratio for spray is 1:1, topcoat to converter, plus 25-35% reducer. With a turbine HVLP system, I found that somewhat higher amounts of reducer were required in order to obtain the best leveling. This also made the paint more susceptible to runs, so it was challenging to find the perfect balance. When properly reduced, the paint leveled beautifully, helping to acheive that perfect gloss and mirror finish. I applied the paint in three coats: the first coat was very light, to cover and tack up the surface for future coats; the second coat was heavier, as needed to cover, and in some cases the second coat could be enough, assuming that any thin spots were covered properly. Usually, however, to avoid overloading the surface, I found that three coats total was the best, with the third coat covering any light areas left behind by the second coat. Painting the 28' hull required only about a quart of the actual topcoat, though this amount was naturally extended by adding an additional quart of converter and 8-10 oz. of reducer. |