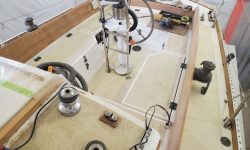

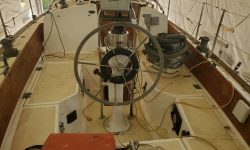

The owner asked me to refresh the nonskid. The existing nonskid was not original, but had been painted with KiwiGrip sometime in the past. Overall, it was still in good structural condition, but the original application was somewhat uneven in texture, though still doing its job. The texture was quite rough and aggressive in many areas.

Because it was well-adhered and in good condition overall, I thought preparing the surface for a new coating of the same material required enough sanding to flatten the peaks, remove some of the texture, and provide a reasonable surface to which the new coating could adhere. I wanted to get all the heavy sanding work out of the way on deck now, before beginning to apply new finishes, so my first step was to sand the existing nonskid with 80 grit, keeping away from the gelcoated borders (though the thickness of the nonskid coating tended to hold the sander up just high enough) and flattening the old texture, though stopping well short of any attempts to completely smooth the surface or remove the old coating entirely. This also did not remove all the discoloration and staining from the depths of the old texture, but I planned to wash the decks next time. This work, and an initial cleanup, consumed the bulk of the day.

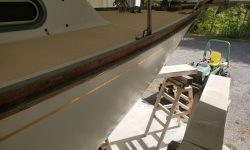

At the end of the day, I took a few minutes to install teak bungs in some unused bolt holes in the anchor platform, where the small anchor roller had been, and to repair one missing bung at the aft end of the port toerail.