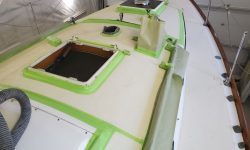

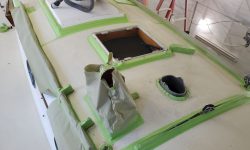

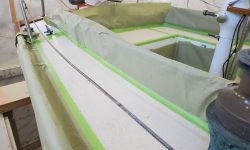

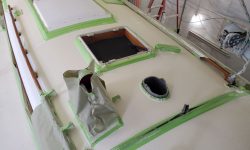

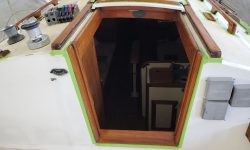

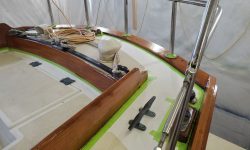

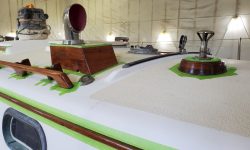

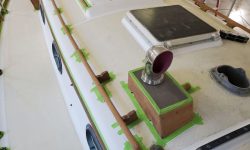

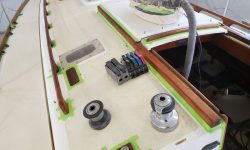

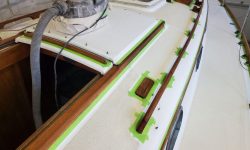

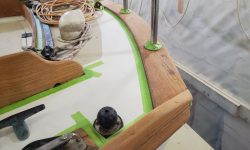

Now that the brightwork had had quite a few days’ cure time, it was safe for me to continue and complete the masking to prepare for nonskid, starting with the cockpit coamings, which I covered completely in masking paper, and then the coachroof, where I fully protected the handrails and other areas with plenty of tape and masking paper to hedge against splatters during the nonskid work. I followed and was bound by the lines of the existing pattern, cutting rounded corners to match where necessary, and forming sharp corners where the pattern dictated. Afterwards, I performed the final cleanup of these areas to prepare for paint.

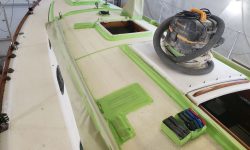

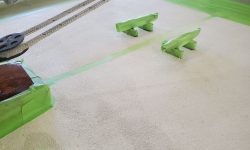

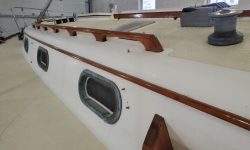

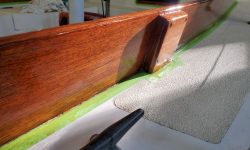

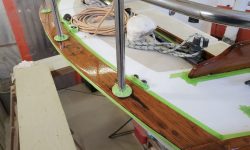

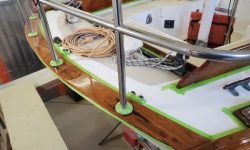

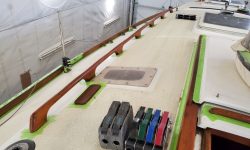

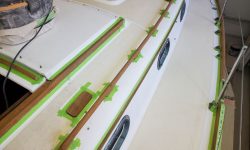

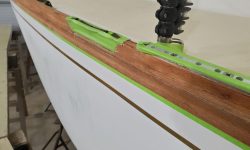

Working from the staging, I masked the sidedecks and foredeck, using paper to protect the cabin trunk and toerails.

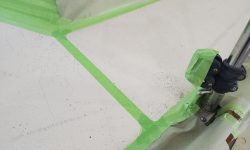

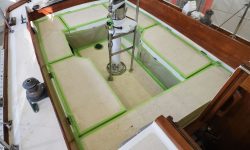

I’d worked steadily to finish up the masking, and found there was enough time in the day to actually paint the nonskid, though I’d anticipated doing it on a separate day. After getting set up for paint, I started in the cockpit and cockpit well, where I painted the sole first. I was immediately reminded of why I bothered with all the extra masking and protection, as I’d no sooner started then I had the splatter evidence before me, highlighting exactly why it was worthwhile. Perhaps there really is a way to apply this paint without the splatter, but I have not found it.

I finished painting the cockpit sole, an awkward proposition, and pulled the tape immediately adjacent to the fresh paint, throwing it over the side of the boat to get the messy strips out of the way. My masking so far had worked pretty well, but as always it was hard to find the tape ends once covered in paint, and removal was a messy and delicate operation, extra-challenging in the depths of the cockpit well.

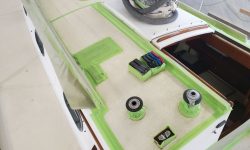

With hopefully the most difficult part of the job behind me, I continued with the cockpit seats and locker covers, working my way around and pulling the tape from each section once complete, till the whole cockpit was done. So far, the improvement in appearance was dramatic.

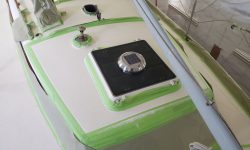

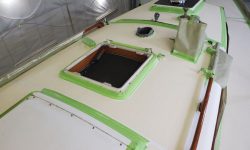

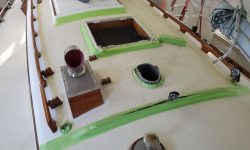

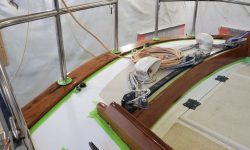

Next, I painted the coachroof, section by section. Here, I had some challenges with the unmasking despite my best efforts, mainly in locating the ends of the tape to start pulling, but as always I persevered. When the tape ripped during removal, or left its bottom layer behind, I simply left it, but I got most of the edge tape removed cleanly. I left hardware fully masked for now, and would deal with its unmasking once the paint was cured. Even with all the extra masking I’d done, I still had to remain vigilant for stray splatters beyond the confines of the tape and paper, ready to wipe them up with a water-dampened rag (Kiwigrip is water-based).

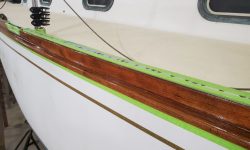

After a short break, I cleaned up the sidedecks, which I’d had to walk on for the rest, and then started painting again with the foredeck on both sides, before working my way down the starboard side, and then back up the port side to complete the job. I pulled the strips of tape bordering the nonskid and left the remaining tape and paper in place till the paint had a chance to cure overnight and/or was safe to work on and around.