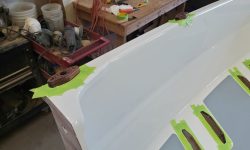

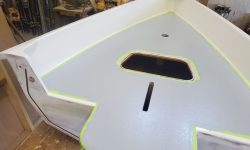

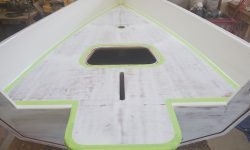

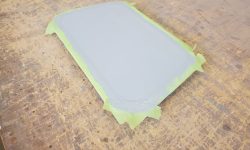

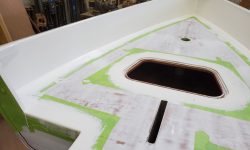

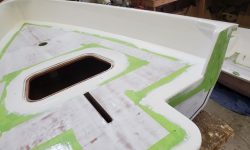

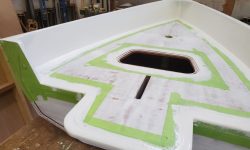

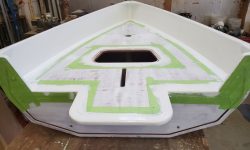

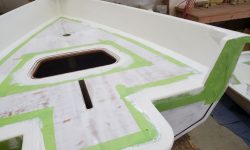

Now that the fresh nonskid had had another full day’s cure time, I felt safe to remove the remaining masking tape from the food cleats and other wooden installations inside the boat. I was disappointed to find that the paint had bled beneath the tape in several areas, staining the varnish work, so I resolved to lightly sand off the offending paint and revarnish all the bits and pieces; I needed to varnish the aft seat cleats anyway, as I’d installed bungs and sanded the faces when I installed those cleats a while back, and hadn’t had a chance to finish up the varnish work there.

With the cleats and rowlocks thusly prepared, I masked around everything and applied a coat of varnish all around. Just the one coat would be required everywhere as a touch-up, as there was plenty of buildup on all the parts. I didn’t include this time in the day’s billing.

Later on, I removed this masking tape.

In other works, I took the opportunity (before varnishing) to clean up a few paint drips that had ended up on the hull, mainly on the transom and stem. I used light scraper pressure to remove the bulk, then lightly sanded.

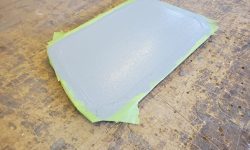

With time left in the day, I turned to some small jobs I could complete on the rudder and daggerboard assemblies. The starboard side of the rudder case required squaring the rudder bolt hole (created in overfilled epoxy) to accept a carriage bolt, so I took care of this task with a chisel, having first marked out the rough square with masking tape around the hole.

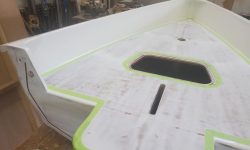

Next, I installed the pintles, a relatively straightforward task. There were scribed marks on the forward edge of the rudder case on both sides, which marks indicated the pintles’ positions, so I followed the instructions to lay out the initial screw holes 3/8″ in from the forward edge at the scribe mark, and dry-fit the pintles with just the one screw on each side. Then, I carefully adjusted their position so the pins were straight and inline with one another, and appropriately spaced from the rudder case itself, and drilled and dry-fit the second set of screws on each pair. The book called for setting these screws in epoxy, which was my final step.

While I had a small batch of epoxy going, I drilled a hole for and installed a hold-down pin at the forward top edge of the daggerboard. There’d be some corresponding hardware mounted to the foredeck itself to finish off this little bit later on. For now, I propped the daggerboard with the pin facing up to keep it secure while the epoxy cured.

The rudder blade got secured to the rudder case with a carriage bolt and hand wheel on the opposite side, making it easy to secure the blade in any position, from kicked up to the sailing position.