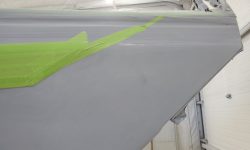

To get started, I masked off the raised sheer strake–which would be painted a trim color later–to protect it while doing the main part of the hull. I masked along the bottom edge, keeping the tape just a bit shy of the juncture between the proud sheer strake section so that when I masked for the trim, I could bring the tape down onto the flat of the hull and be ensured of good hull paint coverage beneath. At the forward and after edges, I struck curves to replicate the originals, and filled in the field with additional tape.

Next, I moved the staging out of the way so I could strike the new boottop, which required two lines: the bottom line, set 1″ above the waterline as previously marked; and the top line, which would be 3″ above that for a 3″ visual height (matching that of the original striping). In my habitual and well-described manner, I set up horizontal, level beams fore and aft at the proper height, then, with a taut line strung between the two, incrementally pulled in the line from roughly midships towards each end in turn, marking where the line touched the hull at each move (and masking it in place so it wouldn’t move further). In this way, I established a series of tick marks on the hull against which I could mask the lower edge of the boottop.

With the lower line struck on both sides, I installed 3″ wide boards atop my originals, clamping them in place to establish the height of the top of the stripe. This seemed quicker and easier than relocating the original beam itself. Then I repeated the marking process to establish the top of the new stripe. After breaking down the ends, I masked inside the new marks to cover the eventual boottop area for now, and this also gave a chance to critique the new lines visually.

At the bow, I established a new mark 1-1/2″ higher at the stem, then created a sheered, or raised, section of the stripe at the top edge, starting from a point 10′ aft along the waterline. Without this additional height forward, the otherwise visually straight line always appears too narrow at the bow, but the subtle increase in height stopped far sort of being immediately noticeable in its own right. However, it made the striping look “correct” in the flared bow sections.

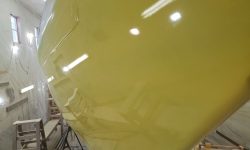

Now I could reset the staging at a height appropriate for working on the hull (I went one level lower for most of the planks than before, as I’d found during the primer coats that I was too high in the after sections of the boat), then worked on final preparations, including a final solvent-wash and tack off, additional lighting to highlight the hull and make it easier to find my wet edge while spraying, and all the other things I do to prepare for paint day.