The main bulkheads continued to be my priority, and to get started I trimmed the overhanging fiberglass from around the edges, and the hardware holes, and with a sanding block finished the edges back to the original plywood. For the moment, I left the glossy epoxy surfaces alone, but they’d get sanded before installing the bulkheads.

With both bulkhead sections trimmed as needed, I assembled the two pieces together using the two dowel pins designed for the purpose. These pins fit in the two small holes at the top edges of the bulkheads, and aligned the sections well. The large hardware holes lined up well, and as directed I cleaned these openings up a bit with sandpaper to ensure perfect alignment through both bulkhead sections, and from both sides.

With preparations complete, I epoxy-coated the insides of the hardware holes as indicated in the manual, and epoxy-coated the mating faces of both bulkheads; these were the sides opposite those that I’d treated earlier. Now the bulkheads had to cure before I could proceed with the next steps.

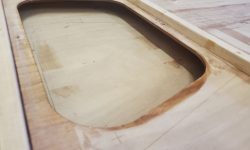

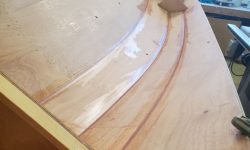

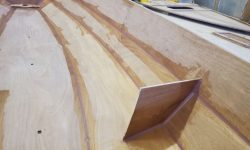

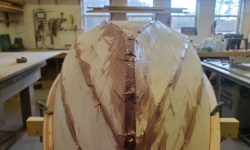

Turning to the foredeck, I trimmed the excess fiberglass as needed and block-sanded the edges back to their original shapes all around, as well as on the deck hatch. Again, for the moment I left the glossy top surfaces unsanded, as it would be easier to sand this epoxy after additional cure time. I flipped the foredeck over, and after some minor sanding work to ease the edges of the various cleats and structural members, I coated the underside with its first of two coats of epoxy, including the structural members and the curved edge doublers. I left the area around the hatch opening uncoated, as soon I’d be installing the plywood hatch coaming in this area. This coat of epoxy was designed to stabilize the foredeck and avoid any wood movement now that one side was glassed and coated; the final coat of epoxy on the underside wouldn’t occur till after the foredeck was dry fit in the boat, a few steps down the road.

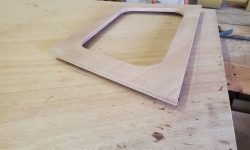

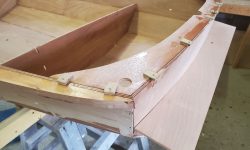

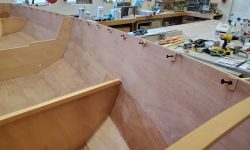

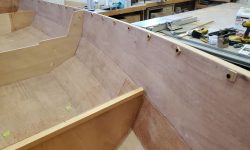

A significant structural aspect of the boat and its ability to be in two halves would come from a series of plywood gussets to reinforce the main bulkhead on each side. These gussets came pre-shaped in the kit. and as I perused the manual and with installation pending, I saw that it was advised to pre-coat these gussets with epoxy, so after a light sanding to clean up the parts, I rolled on one coat of epoxy on the exposed edges, top, and bottom, leaving the straight/square faying surfaces uncoated.

Throughout the build, I’d striven to stay several steps ahead and ensure a continuous work flow, with various side projects to turn to at any given time, but now, with the substructures all built as far as they could go and awaiting the inevitable epoxy cure time on crucial pieces, I was frankly running out of things to do. If I could go back in time, I would have removed the main bulkhead from the hull quite a bit sooner, and then could have had the time-consuming epoxy work (time consuming only by nature of the required cure times) underway in the background. The bulkhead could have come out of the boat anytime after the chines were glued from outside, and while I frequently read ahead in the manual, this didn’t jump out at me ahead of time, particularly as I had already found three or four other sub-projects to move forward with in the meantime. But now it would have been helpful if I’d had the bulkhead pieces ready beforehand.

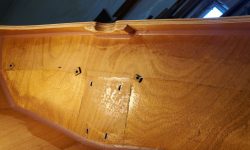

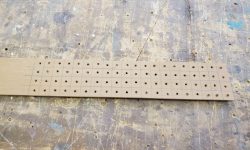

In any event, I’d soon be back at work with the bulkhead, but for now I turned to a small job: installing a structural tunnel for a towing line/painter. The kit included a small 3/4″ diameter fiberglass tube for this purpose, to be installed just aft of the stem. With the chine fillets in place, I could proceed with this. I began by marking the hull on each side as directed in the manual, and drilling small pilot holes to check the location from inside. Satisfied with where the holes fell, I enlarged the pilot holes to 1/4″, drilling from each side first, but then ensuring that the drill bit passed straight and cleanly through from side to side, and finally drilled 3/4″ holes with a hole saw to accept the tubing.

The tubing fit right where it should, basically resting against the inside of the inner stem bulkhead, and now I taped it in place from inside and secured it around its outer edges with epoxy. To speed things up, I used shop epoxy for this, as it would cure more quickly.

Indeed, after lunch I found things had set up enough that I could proceed with the final epoxy work to secure the tube from inside, which involved two sections of 6 oz. fiberglass set over a mass of thickened epoxy that I installed around the tube and nearby corners. The fiberglass tied the tube into the sides of the hull, the inner stem, and extended down over the centerline and onto the bottom plank of the boat, covering the fillet I’d installed during the stem construction earlier.

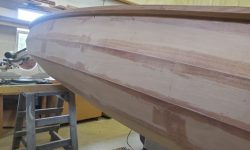

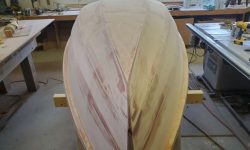

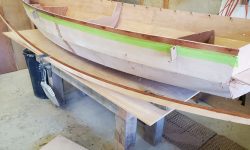

Finally for the day, I turned the hull over and, after final preparations, fine-tuned the hull seams as needed, using a thickened epoxy mixture to fill any tiny low spots and clean up the chines, transom corners, and bulkhead slots as needed.