110 Cookson Lane | Whitefield, ME 04353 | 207-232-7600 | tim@lackeysailing.com

With a router and a bearing-guided flush cut bit, I trimmed around the four port openings in the main cabin to remove the overlapping plywood.

Afterwards, I bored the holes for the port frame mounting studs. From outside, I used a 5/8" bit in the existing holes to mark the centers, then drilled 1/8" pilot holes from outside in to mark the locations. Inside the boat, I centered my 5/8" Forstner bit on the pilotholes and drilled through the plywood. Then, I used a large countersink to slightly bevel the holes from the inside, as directed, and also sanded a light bevel in the plywood around the newly-cut openings. I also performed these latter steps on the four forward ports.

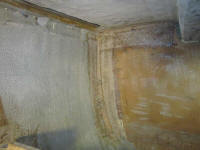

Following the usual water wash, I lightly sanded the new tabbing in the galley and icebox areas, and sanded clean the remaining area of the cockpit locker bulkhead in way of the plywood seam.

After cleaning up, I installed a layer of tabbing over the forward side of the cockpit locker bulkhead's seam to complete the job of tying the bulkhead back together after removing the blocking that had originally held it together. Meanwhile, I installed a piece of tabbing at the bottom of the galley cabinet, covering a seam between some plywood at the base (extending over towards the center of the boat) and the adjacent hull, if only to keep the area cleaner later.

I turned my attention to the forward cabin. While awaiting the new water tanks and icebox to be built, there wasn't too much more I could do in the galley and saloon, so in the forward cabin I made paper patterns of all the bulkhead surfaces, which I'd cover with cherry veneer plywood. I followed my habitual process and made six patterns of various areas, working my way aft towards the passageway and saloon.

At this time, I decided to remove some wobbly old vestiges of the original head doorway openings, and related teak edge trim on the bulkheads in the forward cabin. I suppose I'd left these various pieces in place during original demolition stages because the path forward was less clear at that time, but there was no way these old materials would be suitable going forward, and would also be at odds with the chosen wood species and appearance of the interior. The head doorway trim was already broken (and previously repaired) from ages past. All the trim was secured with screws and easily removable; I saved the pieces for patterns, though I suspected various minor manipulations going forward would likely mean that new trim would be designed on the spot. I also removed some minor trim around the hanging locker opening.

Total Time on This Job Today: 7.75 hours