110 Cookson Lane | Whitefield, ME 04353 | 207-232-7600 | tim@lackeysailing.com

I finished up the final paint/debris removal from the port cockpit seat gutter, scraping and sanding it to a state of relative smoothness. Like the other gutters, years of collected debris and moisture had checked the gelcoat, here worse than elsewhere, and would require minor repair.

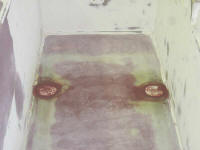

After cleaning up, I smoothed some epoxy fairing compound into various sections of the cockpit seat and locker gutters to clean up the surface and better prepare them for primer and paint, filling in gouges, scrapes, and the gelcoat interruptions as needed, and also filled the edges of the cockpit well, where the old nonskid pattern had ended, and which I'd not done previously.

After some minor fine-tuning for a better fit, I reinstalled the cockpit scupper fittings in a bed of epoxy to form the shaped recess for the fittings. I covered the fittings with clear plastic tape to protect them and act as a release agent when the epoxy was cured.

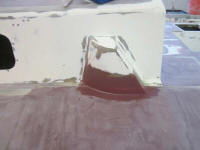

During the deck recore, I'd removed the bottom inch or two of the molded coaming blocks, which projected from the aft part of the cabin trunk and were in the way of reglassing the deck repairs. Now it was time to rebuild and reshape these sections. Using some scrap 3/8" Corecell foam, I cut and fit narrow strips to fit inside the openings, using a heat gun to slightly thermoform the foam into the curve. I tacked these strips in place with hot glue. These foam strips, while eventually becoming part of the structure, would act mainly as molds to reglass the lower portion of the coaming blocks.

Then, I cut off the overlong aft end at the appropriate angle, and filled in the small space on the flat at the aft end. I performed this process on both sides of the boat. With epoxy fairing compound, I applied a coat over the entire area, forming a fillet along the deck for the appropriate transition. I'd hoped to do the filleting and glasswork more or less in one step, but quickly realized that it'd be easier to form the basic shape (with the compound) in two separate applications, as I wasn't able to get the precise shape I wanted in one fell swoop, so I left the first application to cure before proceeding.

Total Time on This Job Today: 5 hours