110 Cookson Lane | Whitefield, ME 04353 | 207-232-7600 | tim@lackeysailing.com

In order to finalize the work list, the first order of business was to inspect a couple places on the hull that the owner had pointed out, and which needed repair of one form or another. Ultimately, the extent of repairs necessary might dictate the course of other portions of the project.

There was a small abraded area on the bottom of the small skeglet running down the center of the bottom. I determined the damage was cosmetic, and would be a relatively straightforward repair. I noted the salient details in order to prepare a repair estimate.

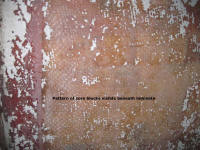

The second area of concern was along the lower part of the port topsides, just above the waterline and beneath an external spray rail. The owner had pointed out a series of fine cracks over this area, which, initially, seemed to be of a minor nature. At the time, during the boat's initial delivery to the shop, we didn't delve further into the causes or the construction of the boat, and the boat remained in outdoor storage for a couple weeks while I finished up ongoing projects. Unfortunately, the pattern of cracks and other external damage was too fine to show up well on camera, but the area exhibited fine cracking throughout a narrow but long section of the hull (at least as visible beneath the paint), with a few areas showing signs of minor laminate cracking and small areas of breakage.

With the boat now in the shop and ready to begin the project, it was time to address the port topsides in greater detail.

My first note of concern came when I went aboard to the boat to check inside the cabin to determine whether the spray chine was screwed in, or through-bolted; I needed to know this in order to prepare an estimate for what I originally thought would be the minor repairs required to the hull, as the means of attachment would dictate how long certain parts of any repair would take.

The forward cabin was the only place where the inside of the rail's fasteners might be noticeable, as much of the after portion of the rail was below the permanent cockpit sole and not visible. Because much of the paint had worn away from the inside of the hull inside the port cabin, I could see through the fiberglass and noted what appeared to be core within; I'd not previously known that the hull was of cored construction.

My heart sank when I noted that the hull was cored, and also that the spray chine was roughly screwed through the hull; the sharp ends of the screws were visible inside the hull. This in and of itself was not necessarily a problem, but the mere presence of core, coupled with what clearly appeared to be less-than-meticulous installation of the spray rail, was an ominous sign. Still, I was completely unprepared for what I found outside the boat.

Having determined that the rail was screwed, not

bolted, in place, I began to inspect and percussion-sound the port

hull in the areas of concern. It immediately became clear why

the hull exhibited the stress cracking seen beneath the paint

surface: sounding results with a steel hammer were indicative of

fully or partially damaged core, so the essential structure of the

hull in this area was weakened, allowing the flexing that could

cause such external cracking.

During a preliminary discussion of what we thought was minor hull damage, the owner had mentioned that he recalled a situation where the spray chine might have ridden up on a low docking float, which could have exacerbated the issues seen during this inspection. The fact that the core was damaged, thereby weakening the hull in this area, certainly explained the visible clues on the outside of the boat.

During a preliminary discussion of what we thought was minor hull damage, the owner had mentioned that he recalled a situation where the spray chine might have ridden up on a low docking float, which could have exacerbated the issues seen during this inspection. The fact that the core was damaged, thereby weakening the hull in this area, certainly explained the visible clues on the outside of the boat.

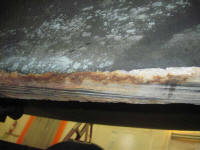

Sounding beneath the hull on the port side aft, I

noticed droplets of water emanating from the bottom just forward of

the transom; closer inspection revealed two areas containing cracks

in the hull laminate, through which the water (which was clearly

contained within the core and laminate) appeared to be slowly

leaking. The darker smudged areas seen in the photos below

are where I ran my finger through the water droplets, located right

at the laminate cracks.

Continuing the sounding in this area and elsewhere along the entire length of the port spray chine, I eventually determined a rough outline of hull sections containing damaged core material. The largest incorporated the externally-damaged area as indicated by the stress cracks, and extended roughly eight feet fore and aft, as high up as the spray chine, and past the turn of the bilge towards the garboards, encompassing a significant portion of the port quarter of the hull, at least 32 square feet in this single area, plus the additional areas as noted.

Sounding revealed another area just beneath the spray chine, and nearly amidships, a bit forward of the largest area. This section was much smaller in scope. In the photo below, the section in question is marked with green tape, just above the set of rollers mid-frame.

I decided also to sound the starboard side of the

hull, concentrating around the length of the spray chine, but also

into the bottom sections. Fortunately (a relative term), I located

only one suspect area on the starboard side, a bit aft of amidships

and just below the turn of the bilge.

I was shocked and disheartened by my findings, and in a detailed email immediately let the owner know what I'd found, the scope of which was unfortunately far beyond what I imagine either of us had anticipated. As of this writing, the status of the project was pending.

Total Time on This Job Today: 1 hour