| Circe

| Thursday, March 4, 2010 First, thing, I cut a fiberglass backing plate to fit the forward cleat, and, after drilling the four holes from outside to mark its position inside, glued the backing plate to the underside of the deck to allow it time to cure and enable me to permanently install the cleat later in the day. While I had the adhesive going, I also secured a fiberglass pad to the hull in order to mount the electric bilge pump--a remotely-located diaphragm-type pump in this instance. Before securing the 1/2" thick pad to the hull, I drilled and tapped for four fasteners to hold the pump in place on the pad, yet make it easily removable for servicing or eventual replacement. Since I didn't want the epoxy adhesive to fill these screw holes, I left the pump in place while I bonded the pad to the boat. |

|

Next, I prepared all the fastener holes in the coachroof as required: drill, tap, and countersink, as habitual. At this time, I discovered that the fasteners I'd purchased for the two deck organizers weren't long enough, so I had to postpone the installation of these pieces till later, when new, longer fasteners arrived. |

|

|

With all the holes prepared, I moved ahead with the installation of what I could: two winches, two rope clutches, and two handrails. I bedded everything with polysulfide sealant: white for the hardware, brown for the handrails. |

|

|

Afterwards, I cleaned up the excess sealant and tape. |

|

|

With the hole epoxy-sealed, I installed the stainless steel through hull fitting for the mast wiring chase. |

|

|

By now, after lunch, the backing plate for the bow cleat had had sufficient cure time, so I drilled and tapped fastener holes through the deck and backing plate, prepared the fastener holes for the adjacent chain pipe, and installed both fittings, cleaning up afterwards. |

|

|

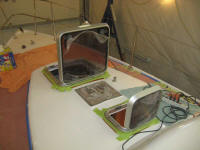

Next: the two deck hatches. Fresh off the truck, I prepared to install the forward hatch, and also the smaller mid hatch that I'd had on hand for a while. I masked off the top of the hatch frames around the hatches, drilled holes as required, and secured the hatches with plenty of sealant, cleaning up afterwards. |

|

|

To round out the day, I sanded and applied more varnish to the companionway trim and galley trim. I also wrapped up a couple odds and ends, including securing the exhaust hoses to some of the new cable clamps I'd installed yesterday, and securing the unneeded propane solenoid wires that I'd previously run into the lazarette. |

|

|