January 8, 2018

Jasmine 24

Monday

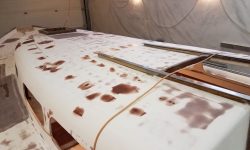

To get started, I applied another round of fairing compound to the fastener holes and elsewhere in the coachroof and sidedecks as needed, taking care of minor low spots after the initial fill.

During an earlier phase of the project, I’d drilled three test holes in the decks that I’d yet to repair–two on the sidedeck, one on the foredeck. During the skim coat, I’d filled the center parts of these holes, but now needed to install some fiberglass over the top, in some pre-ground areas I’d prepared.

There were several small, abandoned holes in the cockpit that required repair, along with various other fastener holes to fill, as with elsewhere on the deck. Among the areas to repair were an obsolete engine room blower outlet (and the blower itself), an old electrical plug hole, and a hole in the port cabin bulkhead that had contained a 12-volt receptacle. After unbolting and removing the old blower from the back side of the hole in the cockpit well, I prepared this area and the others for fiberglassing by grinding out roughly circular areas to accommodate the patches.

While I was working in the cockpit locker, I removed the old and weak battery platforms, a simple task with a chisel. I planned to rebuild these not only because the originals were damaged and weak, but because the owner also wanted the ability to double the battery capacity in the future.

In addition, I prepared various fastener holes, including the original coaming bolt holes, for filling as a matter of course, and bored out the mast step fastener holes and those for a deck plate above the engine for filling and core isolation later.

After cleanup, I filled the various holes and skim-coated the cockpit sole and seating areas with epoxy fairing compound.

Elsewhere in the shop, I sanded as necessary the various loose hatches to remove the nonskid pattern as needed and prepare the hatches for additional work. Then, I applied a skim-coat of epoxy fairing compound to fill and smooth any vestiges of nonskid pattern and repair small voids as needed.

Total time billed on this job today: 6 hours

0600 Weather Observation: 12°, cloudy. Forecast for the day: Clouds, snow showers and light snow in the afternoon, 20s