January 30, 2017

Halcyon 22

Monday

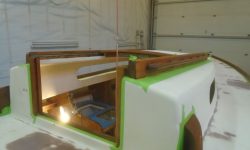

In the cabin, I set about removing any remaining trim from the galley and “head” areas, including the flip-up, hinged countertop/lid over the head compartment. This cleared the way for resurfacing the counters and refinishing the surrounding woodwork and paintwork, I also removed the small longitudinal bulkhead that had closed off the head area, since one side was already loose and it’d be far easier to work within once the piece was removed.

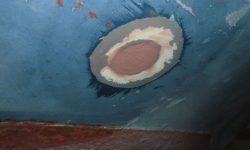

There was an obsolete through hull discharge from the long-removed marine head, and I removed this now, cutting through the fitting from inside and pushing out the recessed through hull, leaving a clean hole behind. Afterwards, I prepared the hull around the hole on both sides, sanding clean the inside surface (and surrounding areas in the compartment) and, outside, grinding a tapered, circular area around the hole to accept fiberglass. Finally, over a couple separate steps, I filled the old hole with a plug of structural epoxy, and when that had cured to a green state, I applied three layers of fiberglass from the outside, and one layer over the inside of the patch.

During the initial cleanup of the space, a quick tap on the old head platform released the last old bolting stud, along with a mess of rusted metal flakes from beneath, remnants of the old backing plate from the ancient installation.

There was a fairly recent repair to the aft, top edge of the centerboard trunk in the bilge, and the owner had asked me to look into it. Not knowing whether there was an ongoing issue or not, I decided simply to reinforce the repair with additional fiberglass, so after final preparations I wrapped new tabbing around the aft end and over the top of the existing repair, extending the new material further onto the original centerboard trunk.

At the end of the morning session, I took the time to solvent-wash all the exterior woodwork, since it can take a long time for the solvent to evaporate out of the bare, dry wood, and I wanted to work on masking and finishing after lunch.

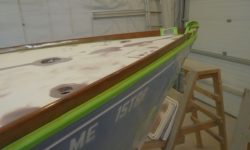

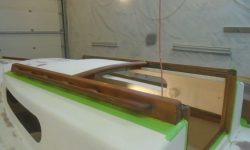

During the afternoon, I masked around all the woodwork as needed, and afterwards applied the first of three coats of Cetol “light” to the woodwork. While the subject of traditional varnish had arisen during discussions with the owner–and real varnish was always my first choice in an ideal world–the existing condition of the original woodwork was such that I felt it made more sense to stick with Cetol for the refinishing, since frankly the old wood wasn’t really worthy of the extra work required for the finer finish, with various old repairs, stains, dents, and the usual collection of wear and tear, along with the natural aging and darkening of the original wood.

This newer “light” version of the original orange-tinged Cetol was lighter and less dense in color, and allowed the grain of the wood to show through more than the original type: a fair compromise in this specific case.

Total time billed on this job today: 5.75 hours

0600 Weather Observation:

24°, clear. Forecast for the day: sunny, 30