110 Cookson Lane | Whitefield, ME 04353 | 207-232-7600 | tim@lackeysailing.com

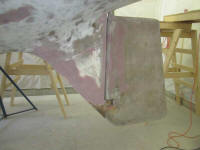

To begin, I finished up the work on the skeg.

Next, I turned to the cabin sides, specifically the interior cosmetic paneling. Earlier, we'd decided on white (or light)-painted wood in these areas to offset the cherry that would cover many other surfaces. To begin the process, I created paper patterns of the two cabin sides in the main cabin, as well as the aftermost bulkheads on either side of the companionway. I cut the paper slightly smaller than the actual size, then scribed the shapes onto the paper using a known offset.

While I had the paper in pace, I traced the port openings from outside to give me a reference for rough holes that I'd cut in the plywood before installation to make installation easier. I'd cut the holes smaller than needed, then trim them to the final shape once the panels were permanently installed.

Down on the bench, I transferred the paper patterns to 6mm marine plywood. The cabin sides were longer than eight feet, so I chose to create the required seam in the center of the forward port openings to minimize its length. Because the final result would be painted, the seam posed no particular problem in terms of appearance.

After marking the cut lines on the plywood, I cut out the various pieces, a surprisingly drawn-out process.

Other portions of the day were filled with a phone conference with the owner regarding various systems choices and installations, as well as other interior decisions in the galley and elsewhere. In between, I confirmed measurements in the galley for the installation of the proposed Engel refrigerator. Meantime, the first parts related to the Sardine woodstove installation arrived from the manufacturer, the bronze deck iron, plug, and smoke cap.

Total Time on This Job Today: 6.5 hours