| Circe

| Friday, February 19, 2010 I continued work on the port side wiring. Picking up where I left off yesterday, I continued the wire runs around the back side of the aft bulkhead, across the back of the engine room, and into the electrical locker to starboard. Then, I repeated the process with three additional pairs of wires for the remaining fixtures on the port side, this time in the galley. I ran these wires up through the countertop behind the cabinet face, where I left the excess for now till I determined where the fixtures would actually be placed. I left a messenger line in place running between the engine room and the galley, which would make it more convenient to run additional wires in the future should the need arise. Afterwards, I tightened and tied up the wire bundle, securing chafe protection where required. The process of sorting out and making final connections of the raw wire bundles at the electrical locker would begin in the near future. |

|

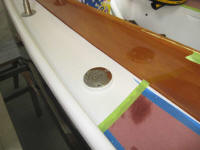

I secured, at least in part, the battery cables running to the engine, and started work on running additional battery-related cables--there'd be quite a few required to complete the charging system, all of which needed to run between the electrical locker and the bilge battery storage area--but abandoned the project when some wire tie supports I'd installed earlier came away from the hull, causing me to rethink the wire runs and means of securing the strap mounts. I also realized that I'd not enough red battery cable in stock to complete the runs, so decided to wait on completing this task till later. Instead, I turned to the fuel system with an eye towards completing it. To begin, I installed the fuel fill deck plate on its new riser, tapping holes through both riser and deck for machine screws. I bedded it well and cleaned up. Then, before installing the fuel tank, which would limit access, I secured a length of fuel fill hose to the deck fitting with a pair of clamps as required. |

|

|

I installed the fuel tank, and secured the fuel fill hose, followed by the vent hose. Then, I completed the fuel supply and return lines, adding a shutoff valve to the fuel supply line at the tank outlet and installing some additional line supports and chafe gear as needed. |

|

|

Finally, I completed the hose connections in the engine room. |

|

|

I started to install the engine exhaust hose, but ran into some questions about clearances at the aft end of the engine, specifically involving the propeller shaft, coupling, and the transmission gear actuator, which was so designed as to impinge upon the space where I'd hoped to run the hose. I decided that it'd be just as easy to run the exhaust hose a little later in the process, so that some of these questions might work themselves out, rather than force the issue now while the questions remained. To complete the day, I laid out the location on the electrical panel for the newly-arrived bilge pump switch, and drilled a hole for its stem. Then I sanded and revarnished the panel. |

|

|