110 Cookson Lane | Whitefield, ME 04353 | 207-232-7600 | tim@lackeysailing.com

The boat had had plenty of time to acclimate and warm up, so my first task was to inspect and percussion sound the entire deck to confirm the suspected presence of core damage on the starboard side deck, and to search for any other areas that might require similar repairs.

As anticipated, the starboard sidedeck, the surface of which was webbed with numerous cracks (which unfortunately didn't show well enough in any photos), was in poor condition over a relatively large area running from the cockpit coaming forward to beyond the chainplates.

A smaller area of the starboard foredeck, beginning at the aft pulpit base, also contained visible surface cracking, and sounding revealed the presence of wet core beneath. A smaller area to port exhibited minor top-skin delamination, as did a similar small section of the port sidedeck.

A heavily-cracked area of the port coachroof, adjacent to the companionway, also appeared to contain soggy core.

Finally, the starboard jib track, located on the coachroof forward, showed surface cracking and evidence of moist core beneath its after end.

Fortunately, the remaining areas of the deck and cockpit all appeared to be in good structural condition with no other unanticipated areas requiring repair.

After discussing the findings with the owner, we decided to proceed with repairs to all affected areas. This broadened the original scope of the project somewhat, as it had been mainly the starboard sidedeck about which the owner had concerns, and the new information meant that we'd be delving into areas we'd not planned.

With the course set, I proceeded with preparations for the work ahead. On the starboard sidedeck and foredeck, I protected the varnished toerail outboard of the two areas to be recored with foam to cushion it from potential impact, then installed plastic over the rail and hull for protection; I also covered the side of the cabin trunk inboard of the starboard sidedeck.

Because the repairs needed to remain within the borders of the nonskid pattern, and to leave sufficient existing material to tie the repairs into, I used 2" masking tape as needed to mark the actual cut lines on the starboard sidedeck and foredeck. Along the rails, the wider border was also required to keep the cut line inboard of the end of the deck core, which tapered away a few inches before reaching the hull-deck flange.

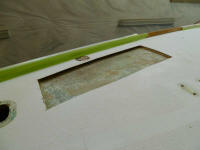

I cut along the lines with a circular saw to release the top skin, beginning with the sidedeck. Because I'd continued the area to be recored slightly farther than I thought the bad core extended, getting started on prying free the forward end of the top skin required a bit of work, but once freed, the remaining section of the sidedeck popped loose almost immediately, as the core beneath was completely compromised.

With the top skin out of the way, I removed all the core from the open areas, pulling most of it out from beneath the remaining deck edges as well; later I'd come back and completely clean out those areas.

I repeated the process on the starboard foredeck. Here, the core damage was more isolated.

Before continuing, I removed the remaining deck hardware from the coachroof--the two jib tracks and a number of fasteners for the dodger and dodger frame. I'd originally left these in place since we'd not planned on doing any work to the coachroof.

Afterwards, I marked what I thought was the rough outline of the core saturation outboard of the port companionway, and cut out the top skin. Once I'd opened up the area and removed the core, I determined a need to expand the opening a bit in order to remove additional wet core.

Re-sounding the area about the starboard jib track on the coach roof, I decided to simply open the area throughout its entire length, as there was an additional questionable spot just forward of my original marks. I cut out the required area and removed the top skin and core.

With all the old core out of the way in all areas, I used a variety of tools to ream out the remaining core from beneath the deck edges where needed, removed the wide masking tape, and prepared for the next steps tomorrow.

Total Time on This Job Today: 7.25 hours